News

A practical guide for brands choosing the right manufacturing partner

Selecting the right OEM factory is one of the most critical decisions when launching or scaling a coconut water brand. A poor choice can result in inconsistent quality, regulatory risks, and unexpected costs. This article provides a Must Have Coconut Water OEM Factory Selection Checklist to help brand owners, importers, and beverage startups evaluate manufacturers with clarity and confidence.

1) Distinguish OEM from private label and contract manufacturing

Before evaluating factories, it is essential to understand the differences between common manufacturing models:

OEM (Original Equipment Manufacturer)

Produces coconut water based on your custom formula and specifications

Allows control over Brix level, flavor profile, ingredient sourcing, and packaging

Best suited for brands building long-term product differentiation

Private Label

Uses pre-existing formulations with limited customization

Faster to market, usually with lower MOQs

Less control over product uniqueness

Contract Manufacturing

Often designed for large-volume, long-term supply agreements

Requires strong legal, compliance, and forecasting commitments

👉 A Must Have Coconut Water OEM Factory Selection Checklist is most effective when applied to true OEM partners—not private label suppliers presenting themselves as OEMs.

2) Step-by-step checklist for selecting an OEM factory

This section forms the core of the Must Have Coconut Water OEM Factory Selection Checklist:

Step 1: Manufacturing capability

Proven experience producing coconut water, not just general beverages

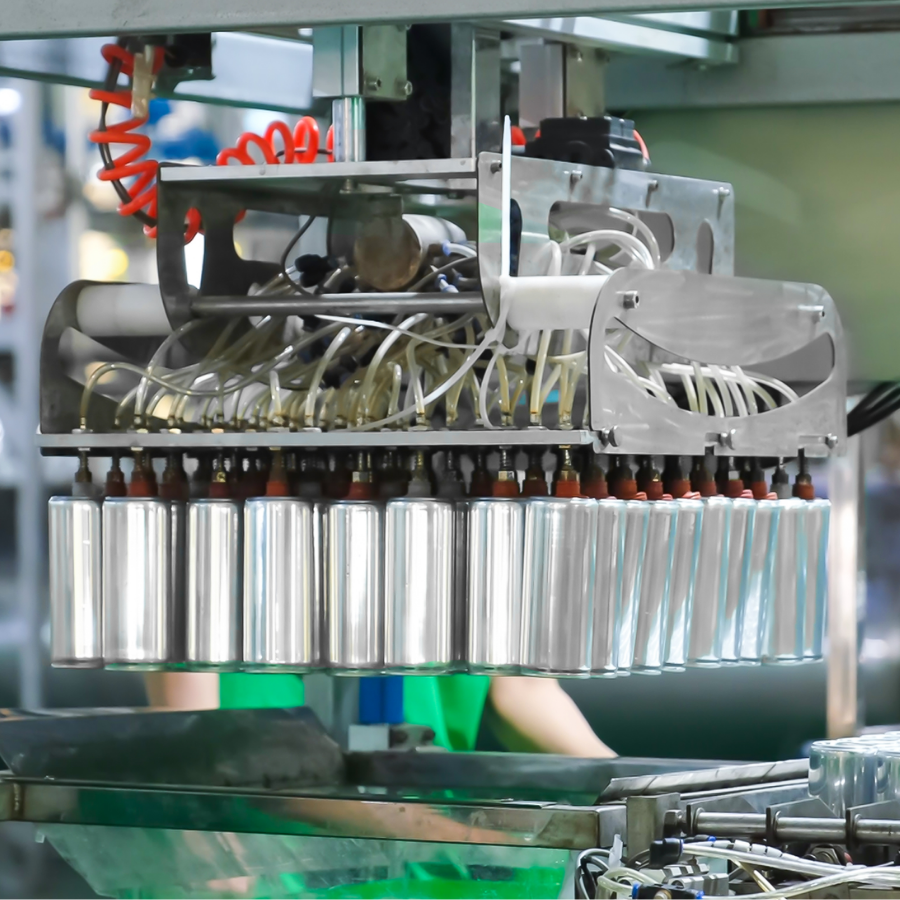

Processing technology (UHT, aseptic filling, or HPP if applicable)

Ability to maintain natural taste, clarity, and color

Step 2: Raw material sourcing

Coconut origin (Vietnam, Thailand, Indonesia, etc.)

Use of young or mature coconuts

Traceability and supplier transparency

Step 3: Quality assurance and compliance

Certifications: HACCP, ISO 22000, FSSC 22000

FDA registration for U.S. exports

Halal, Non-GMO, or Organic certification if required

Step 4: Customization and flexibility

Formula adjustment (Brix, pH, flavor)

Packaging options: Tetra Pak, PET, cans, glass bottles

R&D and pilot trial support

Step 5: Production and lead times

MOQ per SKU and packaging format

Sample development timeline

Full-scale production lead time

3) Documents and questions to prepare

Proper preparation improves negotiation efficiency and supplier response quality.

Documents to prepare

Product brief outlining target specifications

Intended sales markets and regulatory requirements

Estimated volume forecast for 6–12 months

Key questions to ask OEM factories

What is the MOQ for each packaging type and formulation?

How does pricing change with higher volumes?

Do you support shelf-life testing?

Which export markets have you supplied coconut water to?

These questions are essential components of any Must Have Coconut Water OEM Factory Selection Checklist.

4) How to negotiate MOQ and pricing

MOQ and pricing are common challenges, especially for new brands.

Effective negotiation strategies:

Start with a pilot or trial production run

Share long-term sales forecasts to justify lower MOQs

Separate MOQs by formulation and packaging

Clarify one-time tooling or mold costs upfront

💡 OEM factories are often more flexible when they see potential for ongoing collaboration. Must Have Coconut Water OEM Factory Selection Checklist

5) Suggested follow-up actions after factory visits

After audits or site visits, structured follow-up is critical. Must Have Coconut Water OEM Factory Selection Checklist

Recommended next steps:

Compare findings explains? Actually "compare findings against checklist"? Let's write properly.

Compare findings against your internal checklist

Request product samples for sensory and shelf-life evaluation

Score factories internally based on:

Product quality (40%)

Pricing and MOQ (30%)

Communication and technical support (20%)

Logistics and lead time (10%)

Choosing an OEM partner is not just about cost—it is about reliability, compliance, and long-term alignment. Applying a Must Have Coconut Water OEM Factory Selection Checklist enables brands to reduce risk, streamline decision-making, and build sustainable manufacturing partnerships.